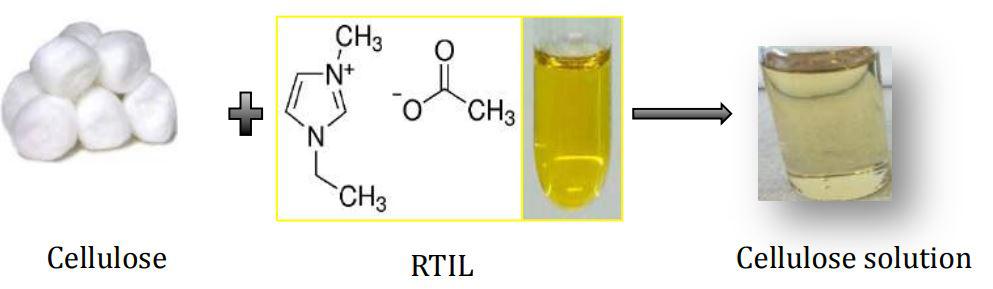

As nanoscale materials make their way into medical applications, biocompatibility is an important issue that needs to be resolved. Nanomaterials may one day serve as the building blocks for nanobots and nanomachines that perform medical functions within the body. We are interested in better understanding the nano-bio interface and the preparation of functional bio and blood compatible nano-scale devices. Nano-bio composites are being prepared by molecularly combine synthetic and biological materials in defined geometries with a wide variety of useful structural and biological properties. With the discovery of room temperature ionic liquids (RTILs), it is now possible to electrospin soft materials that are insoluble in conventional solvents. Such is the case for cellulose which is insoluble in water and volatile organic solvents but is soluble in RTILs.

Figure: A highly complex polysaccharide soluble in RTILs is prepared as a stable composite material. Prepared by Ranodhi Udangawa.

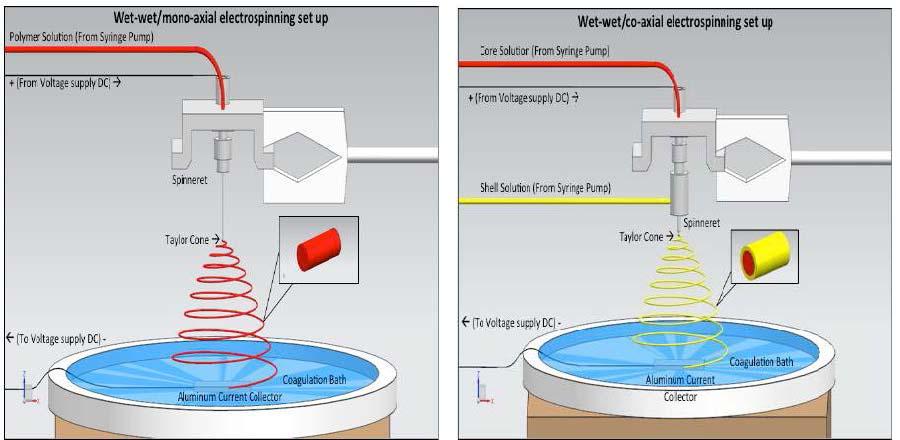

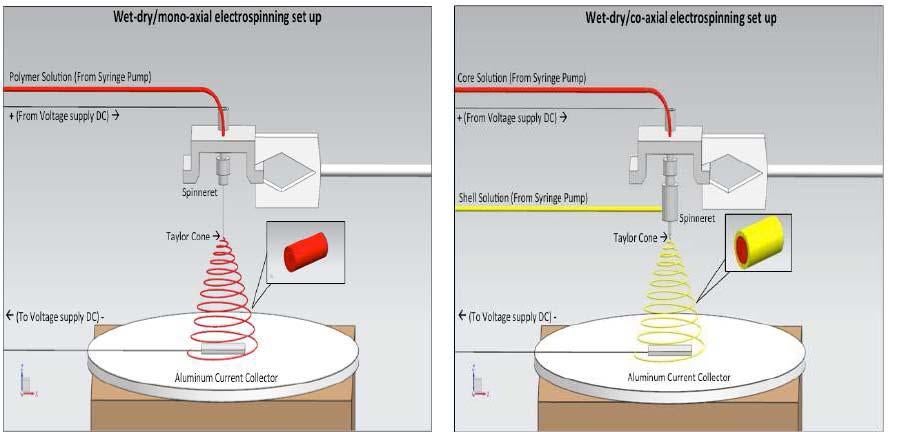

Electrospinning technique is used to prepare nano-scale and microscale fibers. Both wet-dry and wet-wet methods are used to prepare mon-axial and co-axial fibers. The co-axial electrospining of biofibers with supramolecular structures offers potential utility for a number of potential biological/medical/material science applications.

Figure: Wet-wet electrospinning of nano-scale and micron scale fibers. Left-method mono-axial electrospinning. Rightmethod for co-axial electrospinning. Prepared by Charles Willard.

Figure: Wet-dry electrospinning of nano-scale and micron scale fibers. Left-method mono-axial electrospinning. Rightmethod for co-axial electrospinning. Prepared by Charles Willard.

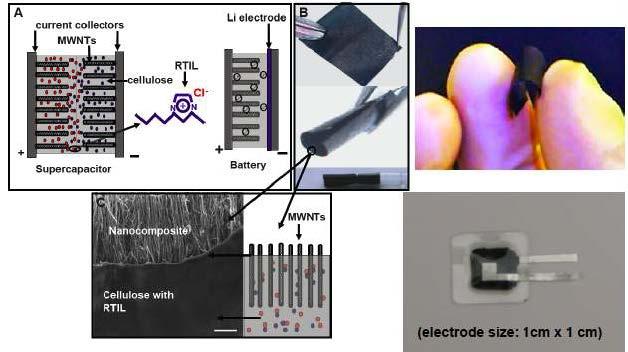

1. Biocompatible energy storage devices for medical applications: Many implantable medical devices (i.e., pacemakers, defibrillators, drug delivery pumps, etc.,) require power to operate. It is often ideal to implant this power source with the device but this then requires surgical intervention to replace or recharge batteries.

Figure. Energy storage solutions. Left to right—a cellulose-based supercapicitor (schematic), SEM, a nanocomposite cellulose-based battery with flexible properties and its schematic.

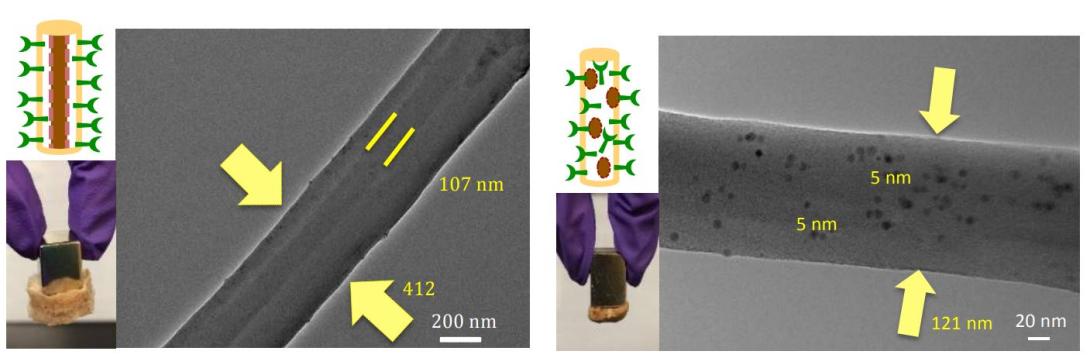

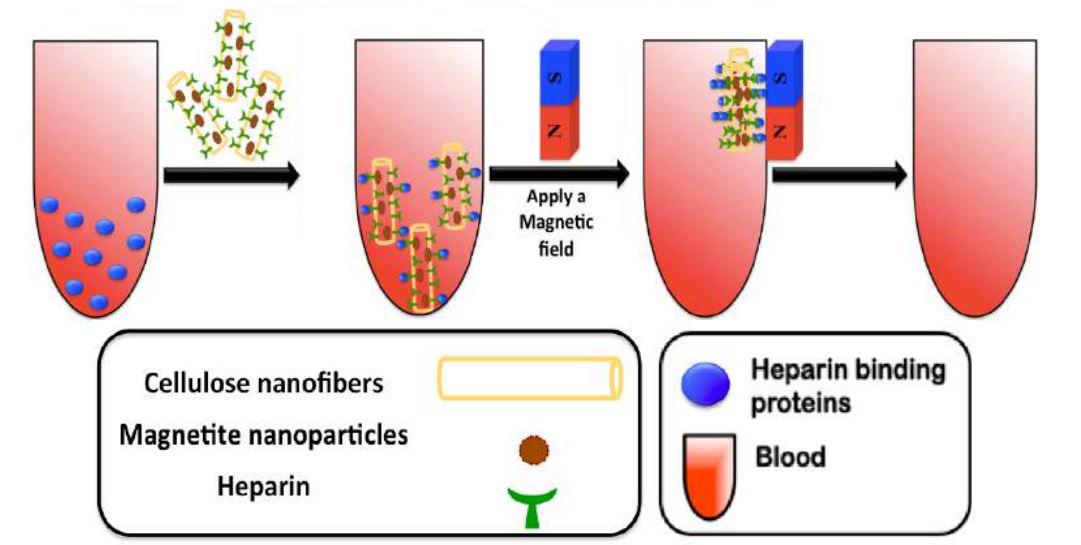

2. Synthesis of heparin immobilized-magnetically addressable cellulose nanofibers for biomedical applications: Heparin immobilized-magnetically responsive cellulose nanofibers were synthesized by wet-wet electrospinning. Superparamagnetic Fe3O4 nanoparticles were incorporated to allow movement of nanofibers using an external magnetic field in both wet and dry states. These meshes can be used in the purification of heparin binding proteins or in blood collection or ex vivo blood diagnostics

Figure: Left- Magnetite-Cellulose core-shell fibers with covalently bound heparin on the surface. Right-CelluloseMagnetite-Heparin mixed fibers. Prepared by Ranodhi Udangawa

Figure: Cellulose-Magnetite fibers with covalently bound heparin on the surface for the use of purification of heparin binding proteins. Prepared by Ranodhi Udangawa.

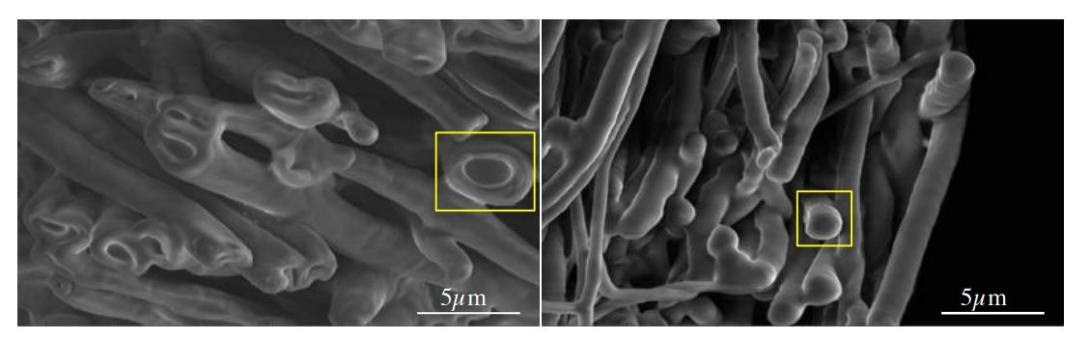

3. Functionalized Artificial Blood Vessel with Heparin: co-axial electrospinning technique has also been utilized to fabricate blood vessel scaffolds from polycaprolactone (PCL) as a shell and Poly(glycerol sebacate) (PGS) as the core. The slowly degrading PCL provides structural integrity and mechanical support while the fast degrading PGS component provides elasticity necessary for blood vessels. The scaffolds are functionalized with heparin to improve the hemocompatibility of vascular grafts due to its high anti-thrombogenic activity.

Figure: Cross-section scanning electron microscope images of 13%PCL-80%PGS co-axial fibers and 13%PCL-m80%PGS mixture fibers. Prepared by Lijuan Hou.

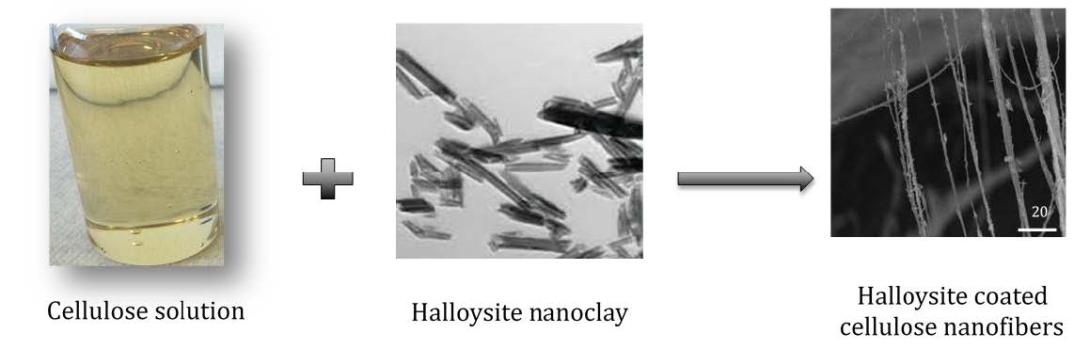

4. Cellulose nanofibers coated with halloysite for rapid hemostasis: There is a great need for fast clotting agents to stop excessive bleeding in surgical theaters and/or battle fields. Nanoclays such as kaolin have been previously shown to induce blood clotting due to their ability to form charged interactions with clotting factors. To maximize their potential, cellulose nanofibers are coated with kaolin to provide larger surface area for blood-clay interaction.

Figure: Electrospun cellulose-clay nanofibers. Prepared by Ranodhi Udangawa.

5. Rechargeable lithium-sulfur battery: The Li–S battery is an ion rechargeable battery that has high energy density. These batteries have the potential to significantly improve using new techniques, such as co-axial electrospinning methods. To produce viable cathodes for lithiumsulfur batteries, we have combined sulfur and carbon nanotubes as the conductive element to use as the core fiber and cellulose as the shell.

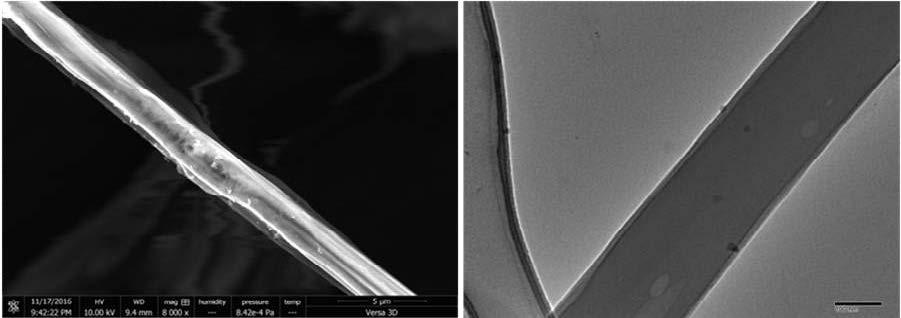

Figure: SEM (left) and TEM (right) images of the cellulose-sulfue/carbon coaxial fibers battery. Prepared by Lijuan Hou

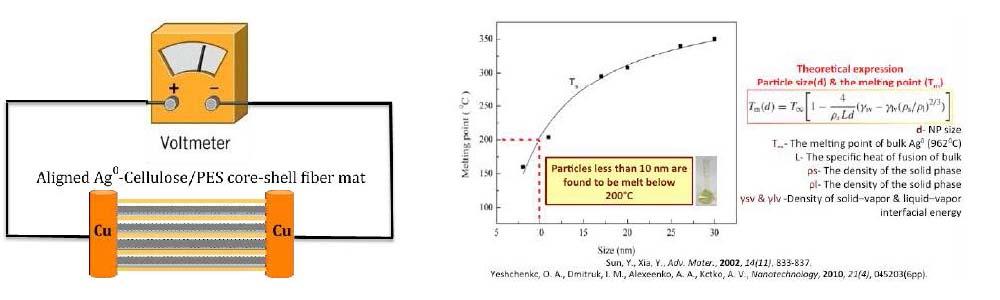

6. Conductive silver-cellulose/PES nanowires: Nanowires allow substantial miniaturization of electronic devices. In contrast to bulk material, nano version of the same material shows better electrical properties.

However, metal nanowires are prone to oxidation. This oxide layer will increase the resistance of the wires decreasing their electrical conductivity. The cellulose (natural) or PES (synthetic) shell provides adequate protection for the unstable metal core. Silver (Ag) is selected because it has the highest electrical and thermal conductivities among all metals. Based on the theoretical modeling, confirmed by experimental data, Ag NPs demonstrate depression of the melting point with decreasing NP size. Potential applications are wearable flexible micro/nano electronics and next generation deformable electronics.

Figure: Prepared by Ranodhi Udangawa.